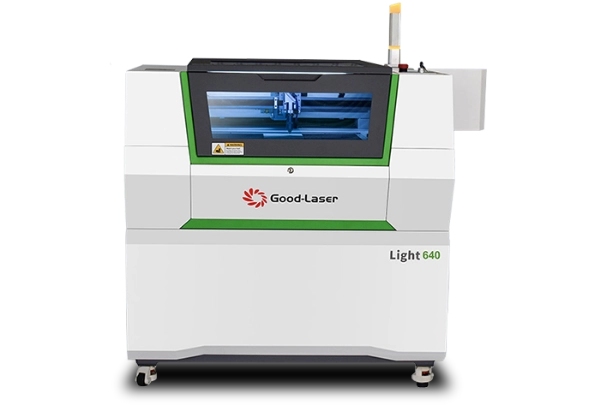

Good-Laser Light 640 Professional CO2 laser cutting & engraving machine

An all-rounder laser cut and engrave machine that beyond expectations All-in-one machine to carry out all your laser creation needs

Empower your laser creation more beyond

We adopted first-class components, high-quality production, and a strict inspection process that aggregated into a high-performance and stable laser machine. With precise cutting and engraving, to meet the laser creation needs of all science and innovation education applications.

And due to its powerful and stable properties, It can be used in personal home use, art creation, science and technology education, and even some industrial and commercial laser production applications.

Faster and Quieter

Shock-proof and high safety thanks to the advanced high-performance hybrid servo motor. It not only supports a working speed up to 1000mm/s but also runs more stably and with lower noise.

Efficient autofocus + red dot positioning

The autofocus function can quickly and accurately focus and locate before cutting and engraving. Coupled with the beam positioned by the red dot to view the working position in real-time, it saves a lot of time and brings better cutting and engraving results.

Multiple official powerful operation control modes & design system

It is so easy to realize your countless inspiration in both laser design system LightMaker on PC and Mobile APP as well. Combined with the 5-inch full-color high-definition touch panel on the machine.

5inch touch panel operating system

The high-definition and full-color 5-inch touch screen machine operation enables simple and intuitive operation of the entire process.

LightMaker APP on Mobile phone

Your mobile phone can also become a powerful laser creation tool with intelligent operation, to realize your laser creation through easy and quickly complete.

Official operating system LightMaker on PC

Good-Laser official operating & design system, compatible with a variety of design software including AI, PS, CorelDRAW, AutoCAD, Solidworks etc…to to upload high-quality JPG, DXF, AI, DST, PNG, BMP, TIF, SVG and other files.

Light 640 Laser Machine Specification

| Specification | |||||

|---|---|---|---|---|---|

| Laser System | Light 640 | Light 960 | Light 1390 | Light 1610 | |

| Laser Tube Wattage | 40-60W | 80-100W | 100-130W | 100-130W | |

| Work Area |

600x400mm (23.6″ x 15.7″) |

900x600mm (35.4″ x 23.6″) |

1300x900mm (51.2″x35.4″) |

1600x1000mm (63.0″x39.4″) |

|

|

Max Part Size (WxLxH) |

Front door closed |

700x530x170mm (after taking out the honeycomb bed) (27.6″ x 20.9″ x6.7″) |

1000x730x230mm (39.4″ x 28.7″ x9.0″) |

1400x1030x230m (55.1″ x 40.6″ x9.0″) |

1700x1130x230mm (66.9″ x 44.5″ x9.0″) |

|

Pass-through door |

700x∞x20mm (27.6″ x ∞” x 0.8″) |

1000x∞x20mm (39.4″ x ∞” x0.8″) |

1400x∞x20mm (55.1″ x ∞” x0.8″) |

1700x∞x20mm (66.9″ x ∞” x0.8″) |

|

| Table Size |

700x530mm (27.6″ x 20.9″) |

1000x730mm (39.4″ x 28.7″) |

1400x1030mm (55.1″ x40.6″) |

1700x1130mm (66.9″ x 44.5″) |

|

| Z Axis Height | 150mm(5.9″) | 230mm(9.1″) | 230mm(9.1″) | 230mm(9.1″) | |

| Dimensions(WxDxH) |

1070x810x610mm (42.1″ x 31.9″ x24″) |

1500x1105x1040mm (59.1″ x 43.5″ x40.9″) |

1900x1405x1040mm (74.8″ x 55.3″ x40.9″) |

2200x1505x1040mm (86.6″ x 59.3″ x40.9″) |

|

| Net Weight | 130kgs(287lbs) | 310kgs(683lbs) | 430kgs(948lbs) | 470kgs(1036lbs) | |

| Laser Type | Sealed CO2 Glass Laser Tube | ||||

| Cooling | Water Cooling | ||||

| Motion Control System | High-Speed hibrid servo motors | ||||

| Maximum Speed | 1000mm/s(39.4 IPS) | ||||

|

Speed and Power Control (engraving depth) |

Computer or manually controlled speed and power from 0-100%. Vector color mapping sets speed and power settings using RGB color mapping. |

||||

| Operating Modes | Optimized raster, vector, and combined mode | ||||

| Resolution(DPI) | User-controlled from 100 to 500DPI(standard laser head), up to 1000 DPI(HR head) | ||||

| Computer interface | Ethernet and USB connection | ||||

| Compatible operating systems | Windows XP/2000/Vista/7/8/10,macOS | ||||

| Buffer memory | 128MB standard | ||||

| Display panel | 3.5″ LCD panel showing current file, total working time, laser power, speed, etc. | ||||

| Electrical requirements | 110 to 240 volts, 50 or 60 Hz, single phase | ||||

| Ventilation System | Integral exhaust fan. There is 1 output port, 24/35:150mm, 51/63:200mm in diameter in the rear of the case. |

||||

Related products

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

-

3MG132G CNC automatic track grinder for ball bearing inner ring

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2070mm*1320mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Contact UsBrushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m

Reviews

There are no reviews yet.