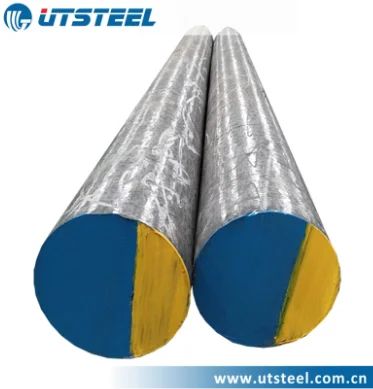

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

https://www.gcmicgroup.com/UT-6523-8620-20CrNiMoA-Cold-Drawn-Bar-Cold-Drawn-Bar-Alloy-Steel.html

UT 1.6523/8620/20CrNiMoA Alloy Structural Steel has High hardenability, no tempering brittleness, good weldability, little tendency to form cold crack, good machinability and cold strain plasticity.

| Steel Grade | 1.6523/8620/20CrNiMoA |

| Dimension | Diameter Ø10-1000mm |

| Delivery Condition | HB≤197 |

| Surface Treatment | Black Surface / Roughed Machined Surface / Turned Surface |

| Production Condition | |

| Stock Quantity | 1000 tons |

| Ultrasonic Test | Sep1921-84 D/D or E/e Under 100% Test |

| MOQ | 10 tonnes |

| Mill Sheet Certificate | Provided |

| HS Code | Hot Rolled:722830 Forged: 722840 |

| Technique | Hot Rolled / Forged |

| Lead Time | 7-10 days |

| Trademark | UTSTEEL |

Chemical Composition(%)

| C | Si | Mn | Cr | S | P | Mo | V | Ni | W |

| 0.17-0.23 | 0.17-0.37 | 0.60-0.95 | 0.40-0.70 | ≤0.03 | ≤0.03 | 0.20-0.30 | / | 0.25-0.75 | / |

Application

UT 1.6523/8620/20CrNiMoA Alloy Structural Steel is normally used in the manufacturing of small and medium-sized automobiles and tractors' engines and gears in the transmission system. It can also replace 12CrNi3 steel to produce carburized parts and cyanide parts with high core performance requirement, such as tooth claws, toothwheel bodies for oil drilling and metallurgical open-pit mine.

Related products

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs! -

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

Reviews

There are no reviews yet.