40KVA/32KW Diesel Generator With Cummins Engine

This 32KW 40KVA diesel generator uses a high-performance 4BT3.9-G2 CUMMINS engine with excellent fuel efficiency and reliability. Suitable for industrial, commercial and emergency backup power needs.

https://www.emeanpower.com/CUMMINS-16KW-780KW/40KVA-32KW-Diesel-Generator-With-Cummins-Engine.html

GENERATOR MODEL: EM-C44

MOQ: 1set

Payment: T/T, L/C,Credit Card

Shipment: 30 days for production or 3days for stock

Package Instruction:Foam film wrapping/Export wooden box

Customized Service: Support(Color, Logo, Style…)

Qualification: ISO9001,CE, SASO

Warranty: 1 year / 1200 running hours

GENERATOR SET SPECIFICATIONS

| Gensets | ENGINE | Alternator | Customization | Option | ||||

|---|---|---|---|---|---|---|---|---|

| Rated Power | 40KVA/32KW | Engine Model | 4BT3.9-G2 | Alternator Model | VG-184J | Voltage: | 110V-660V | ATS |

| Standby Power | 44KVA/35.2KW | Brand | CUMMINS | Rated power: | 32KW | Phase: | Single Phase/ Three Phases | Remote Control |

| Frequency | 50Hz | Engine Power | 36KW | Standby Power: |

44KVA |

Alternator: | Stamford/ Leroy Somer/Marathon | Charger |

| Speed | 1500 RPM | Cylinder | 4 | Insulation Class: | H | Control Panel: | Smartgen/Deep sea | Jacket Heater |

| Fuel | Diesel | Fuel Consumption | 9.3 L/H | Protection Class: | IP23 | Fuel Tank Volume: | According To Requirements | Oil Heater |

| Digital Controller | Smartgen 6120N | Displacement | 3.9L | Trailer | ||||

|

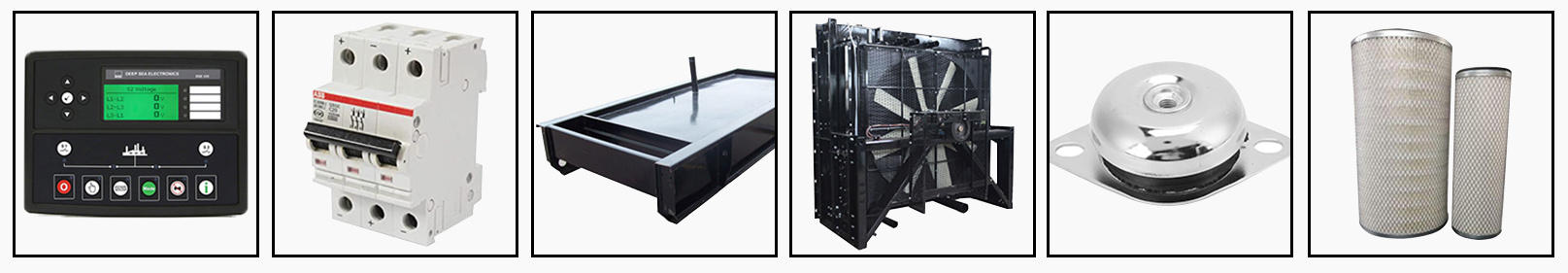

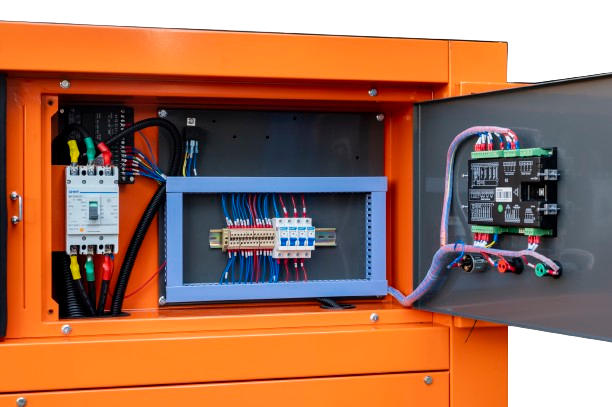

Digital control panel |

Electronic Components |

Thicken Chassis |

Corrosion Resistant Radiator |

Solid Damping Foot |

Filter |

|---|---|---|---|---|---|

|

Integrated digital, intelligent technology, compact structure, simple wiring, high reliability. |

Cooperate with well-known electronic component manufacturers such as DELIXI and CHINT to provide customers with long-life,high-quality and very accurate machines |

5MM thickened bent chassis, double-layer painting, improve corrosion resistance. Prevent the unit chassis from being corroded |

High quality and low noise radiators, with anti-rust paint to add, ensure that your machine will never old, mildew, corrosion resistance, safety. |

Solid damping foot is stamping forming by 3-5 mm high strength steel plate, with metal cover to protect rubber. |

More than 99.5% of filtration efficiency |

|

Our alternator: |

Other factory alternator: |

Our silicon steel sheet: |

Other factory alternator: |

|---|---|---|---|

|

100% copper wire brushless alternator Or original STAMFORD alternator. |

Brush alternator with low quality. |

Use high quality cold rolled silicon steel sheet |

Use low quality hot rolled silicon steel sheet |

|

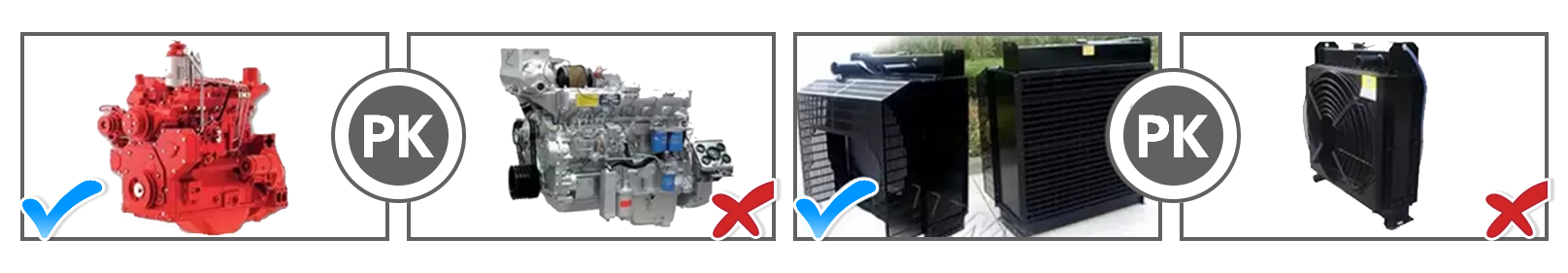

Our engine: |

Other factory engine: |

Our Radiator: |

Other Radiator: |

|---|---|---|---|

|

Branded powerful engine,with global warranty service. |

No Certified, no quality guarantee. |

High quality and low noise radiators, with anti-rust paint to add, ensure that your machine will never old, mildew, corrosion resistance, safety. |

Low quality, high noise radiator, parameter falsification |

Related products

-

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

-

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

-

FS-V-F240 Injection valve

Contact UsFS-V-F240 series drip-proof valve is suitable for direct injection of lithium battery which can efficiently avoid liquid dropping and hanging.

Reviews

There are no reviews yet.