30KVA/24KW 50HZ Diesel Generator With Cummins Engine

GENERATOR MODEL: EM-C33 50HZ ,Power by Brand new water cooled diesel engine

| Gensets | ENGINE | Alternator | Customization | Option | ||||

|---|---|---|---|---|---|---|---|---|

| Rated Power | 30KVA/24KW | Engine Model | 4B3.9-G2 | Alternator Model | VG-184GS | Voltage: | 110V-660V | ATS |

| Standby Power | 33KVA/26.4KW | Brand | CUMMINS | Rated power: | 24KW | Phase: | Single Phase/ Three Phases | Remote Control |

| Frequency | 50Hz | Engine Power | 24KW | Standby Power: |

33KVA |

Alternator: | Stamford/ Leroy Somer/Marathon | Charger |

| Speed | 1500 RPM | Cylinder | 4 | Insulation Class: | H | Control Panel: | Smartgen/Deep sea | Jacket Heater |

| Fuel | Diesel | Fuel Consumption | 6.7 L/H | Protection Class: | IP23 | Fuel Tank Volume: | According To Requirements | Oil Heater |

| Digital Controller | Smartgen 6120N | Displacement | 3.9L | Trailer | ||||

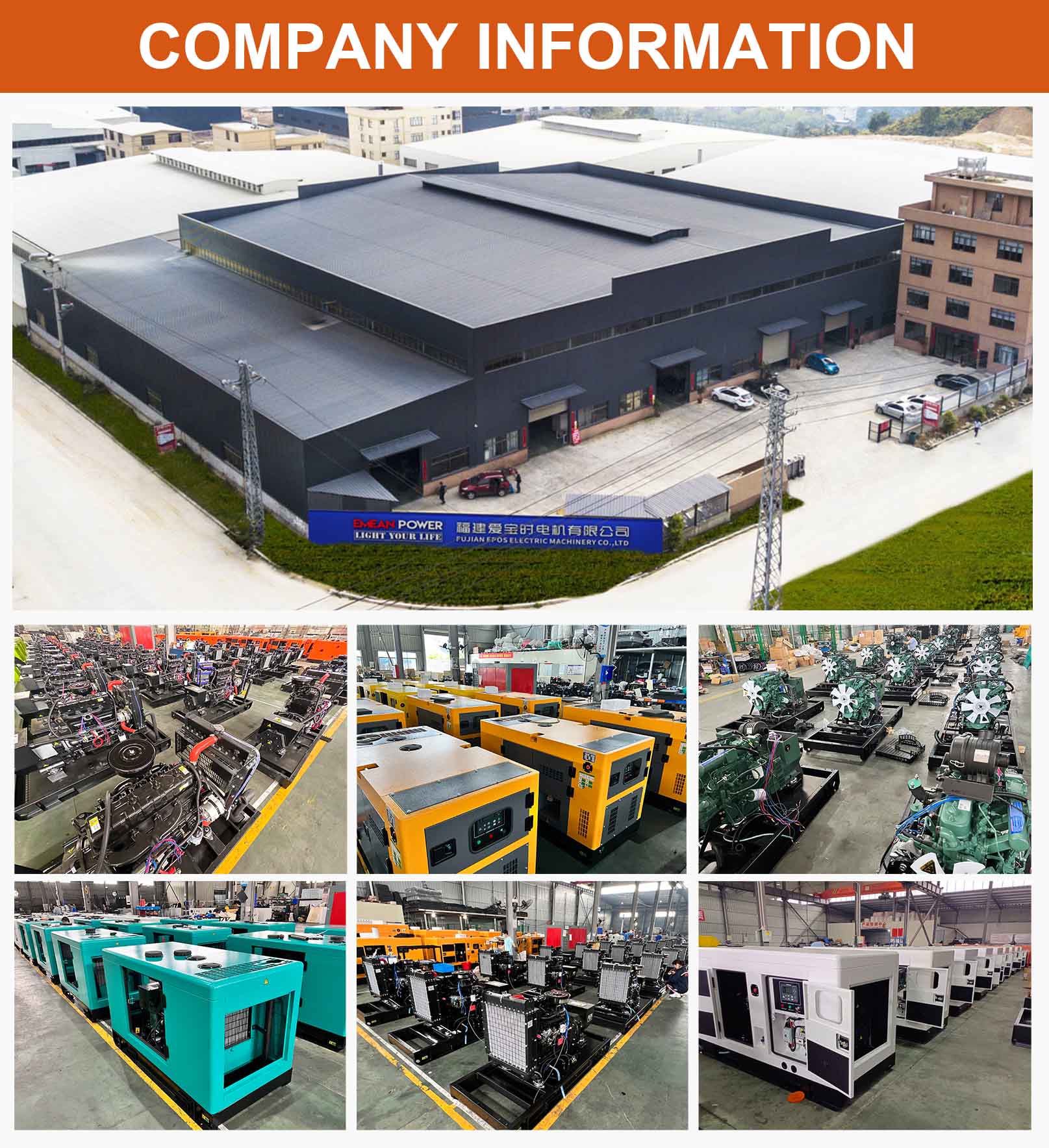

EMEAN POWER is a well-established enterprise with three subsidiaries: Fuzhou Emean Electric Machinery Co., Ltd., Fujian Epos Electric Machinery Co., Ltd.and Fujian Epos Technology Co., Ltd. Currently, we have two factories and one factory under construction.

To date, we have established cooperative relationships with more than 10,000 customers, and our business covers more than 100 countries and regions around the world.

Related products

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

-

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

Reviews

There are no reviews yet.