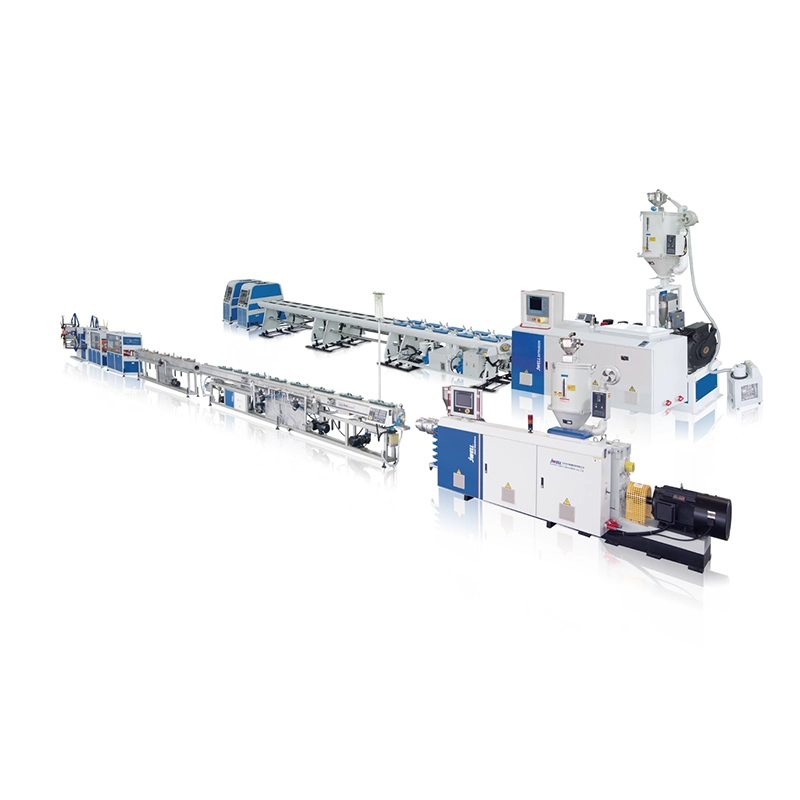

Small-caliber PE/PPR/PE-RT/PA Single-pipe, Dual-pipe High-speed Extrusion Production Line

Performance & Advantages: The main screw adopts BM high-efficiency type, and the output is fast and plasticized well.

Suzhou Jwell Machinery Co., Ltd.is an important development strategic center

and manufacturing base of Jinwei Machinery. It is located in Chengxiang

Industrial Park, Taicang, Suzhou, and is 30 minutes' drive from Shanghai

Hongqiao Airport. It covers an area of 20 hectares, with an indoor area of

120000 square meters. It is equipped with advanced CNC machining base for parts

and standard assembly workshop. With more than 1000 employees, it has a

high-quality design and development team and an experienced team of mechanical

and electrical commissioning engineers.

The company focuses on plastic pipe and sheet film extrusion equipment

manufacturing and various professional technical services, and carefully

manufactures plastic extrusion equipment that meets the needs of global users,

of which foreign trade exports account for more than 75%. Strict design, strict

standardized manufacturing process and perfect after-sales service guarantee

system provide users with efficient, energy-saving and high-quality production

line equipment and considerate services.

Contact whatsapp: 138 1703 9977 / 139 1685 8896 / 139 1887 6278 / 134 7257 0215 / 158 0622 6900

Email: salbn@jwell.cn

Summary

Performance & Advantages: In order to meet market, Suzhou Jwell based on years of experience, independent research and develop of conical twin-screw extruder series FRPP / PVC DWC pipe line, has the following characteristics:

1.The overall energy consumption of the production line is low, the conveyor efficiency of the conical twin screw extruder is higher than that of the single screw extruder, and the installed power is less than the single screw extruder;

2. The powder material can be extrusion directly, use raw material + calcium powder formula, reduce the cost and improve the pipe ring stiffness;

3. The extruder has a vacuum device to overcome the problem of air bubbles inside and outside the pipe due to the moisture content in the raw material.

Main Technical Parameters

| Type | Pipe Spec (mm) | Extruder | Main Power(kw) | Output (g/h) |

| PE/PERT 75 | ∅20一∅75 | JWS-H60/40 | 110 | 380~ 420 |

| 90 | 350~ 400 | |||

| JWS 65/33 | 75 | 200~240 | ||

| PPR 75 | ∅20-∅75 | JWS-H60/40 | 110 | 300~ 340 |

| 90 | 280~320 | |||

| JWS 65/33 | 75 | 160~ 195 | ||

| PE/PERT 32 | ∅16-∅32 | JWS-H60/40 | 110 | 380~420 |

| 90 | 350~400 | |||

| Note:The specifications are subject to change without prior notice. | ||||

Related products

-

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

-

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs! -

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

Reviews

There are no reviews yet.