Overview

Unique spray process, stable welding selection effect, small batch production of preferred welding equipment, low cost, high flexibility

Product features

Special designed point flux injection;

High precision, high stability selection spot welding (single and double head optional)

Nozzle automatic cleaning , automatic calibration of jet height, automatic addition of solder and miniaturization design;

Configure the AIVS manufacturing platform;

Realize the online repair function by connecting AOI

|

Type |

Specification |

Selective wave soldering machine |

|

Technical parameter |

Machine size |

L800*W1400*H1400mm |

|

Mechanical pump groove |

Standard:single cylinder×1个 |

|

|

Spray nozzle diameter |

φ3-12mm |

|

|

Wave height |

Max:5mm |

|

|

PCB gap |

Min:3mm |

|

|

Tin furnace capacity |

8KG/ Solder furnace |

|

|

Soldering temperature |

Max : 320℃ |

|

|

Temperature control accuracy |

±1℃ |

|

|

Heating time |

40Min/(300℃) |

|

|

Tin furnace power |

1KW/ Solder furnace |

|

|

Moving speed |

X/Y:2 – 400 mm/s |

|

|

Z:2 – 50 mm/s |

||

|

Wave accuracy |

±0.5mm |

|

|

Repeated accuracy |

±0.05mm |

|

|

Spray width |

2-8 mm |

|

|

Size of spray nozzle |

130um |

|

|

Spray way |

Linear |

|

|

Pressure |

0.5Mpa |

|

|

Nitrogen consumption |

1.5m |

|

|

Particles cleanliness |

≥99.99% |

|

|

Nitrogen preheating temperature |

MAX:350℃ |

|

|

Temperature control accuracy |

±1℃ |

|

|

Process visualization |

CCD visible |

|

|

Data import |

Measure Gerber、Images imported online |

|

|

Power |

3P5W,380VAC |

|

|

Frequency |

50/60Hz |

|

|

Consumption |

4.5KW |

|

|

Air supply |

0.5Mpa |

|

|

Automatic solder adding device |

Option |

|

|

Nozzle automatic cleaning device |

Option |

|

|

Spray height correction |

Option |

|

|

AIVS Intelligent manufacturing platform |

Option |

Related products

-

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

MA-(2~8MM)×1800MM Steel Coil Slitting Line

Contact UsMA-(2~8MM)×1800MM Steel Coil Slitting Line is mainly composed by the following components : uncoiler, guiding device

-

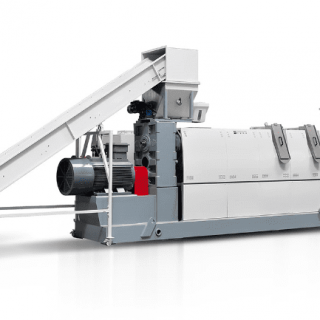

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

Reviews

There are no reviews yet.