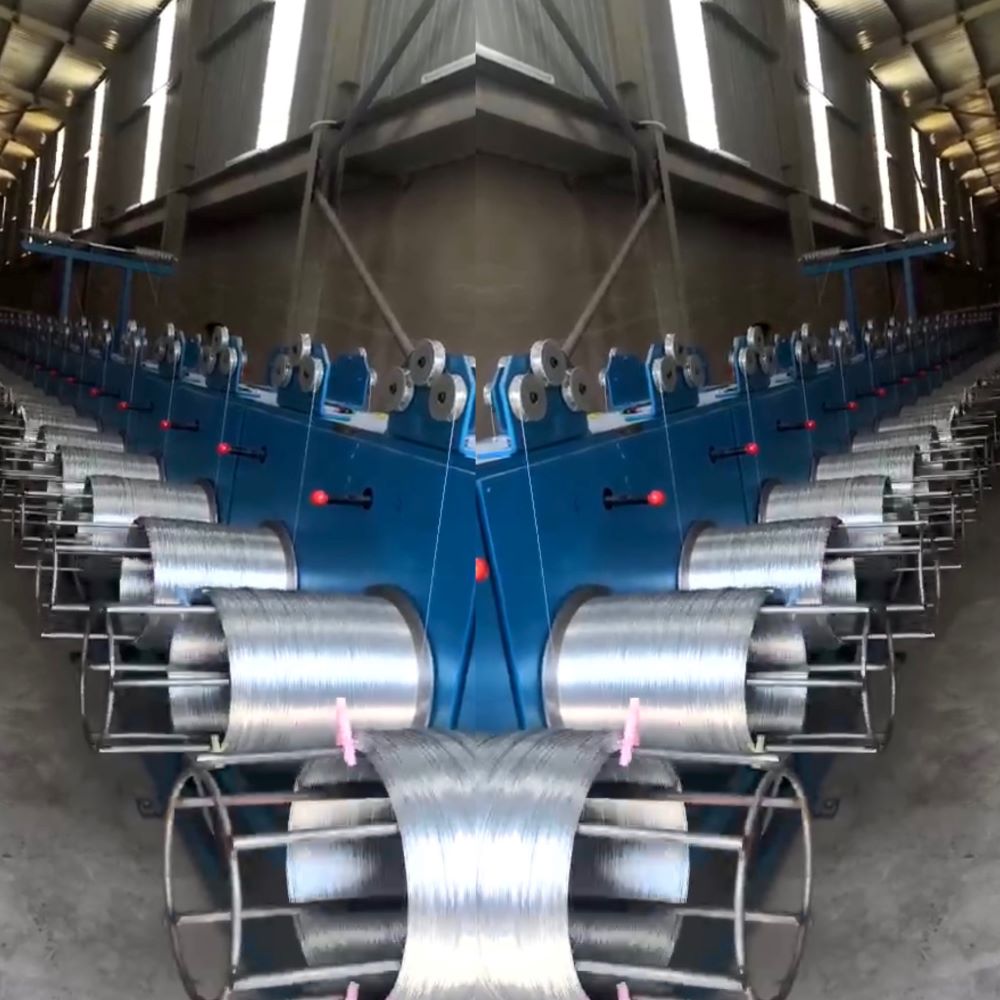

Galvanized Wire Machine

Products: Low ,medium and high carbon galvanizing steel wire, Diameter range: 0.7~1.5mm, 0.9~2.5mm, 3.0~5.0mm As clients requirement Coating Zinc weight range: 5~15 g/m2 ,15~35g/m2

Electric galvanizing design scheme for Low carbon steel wire

I、Design basis:

1、Products: low carbon galvanized steel wire

2、Raw material: Example -SAE1006, Q195 wire

3、Wire diameter: φ0.8—3.0mm

4、Steel wire strength: 350–450Mpa

5、Galvanized layer weight: 10g/m2, tolerance ±1g/m2

6、DV value: 80

7、Line number: 24 lines

8、Wire spacing: 25mm Spacing; Max width Total 2500mm;

9、Height of steel wire from the ground (elevation of steel wire travel): 950mm

10、Wiring method: straight in type

11、Line length: approximately 90 meters

12、Workshop length: straight in type

13、Usage voltage: According to customer requirements, our standard voltage is 380V

14、Output (minimum): > 16T/day (based on ø 1.2mm, 50m/min, 24 hours/day),

> 12T/day (based on ø 0.8mm, 90m/min, 24 hours/day)

According to the factory working efficiency: >75%

Note: This price is according to:

1.Uesd for: mesh wire, building wire, binding wire

2.Product Capacity: As machine normal design speed

3. Electric power resource: 440V, 50HZ.

|

Example galvanizing wire product capacity |

|||||

|

mm |

DV |

hours |

pcs |

efficiency |

Tons |

|

0.9 |

90 |

24 |

40 |

85~80% |

24.43~23 |

|

1.6 |

90 |

24 |

40 |

85~80% |

43.25~40.7 |

|

2 |

90 |

24 |

40 |

85~80% |

154.3~51 |

|

2.5 |

90 |

24 |

40 |

85~80% |

67.88~63.89 |

Process flow:

No.1. Pay-off bobbin→ Space 2.5 meters →No.2. Alkaline water washing (5m)→No. 3. Hydrochloric acid pickling (8.4m) →No.4. water washing (4m)→No.5. electro galvanizing (27m)→No.6. water washing (include hot water washing saponification 4m)→No.7. drying (4m)→Space 2.5 meters→No.8 wire collection take up machine

Acid mist purification tower:

To prevent acid gas leakage and environmental pollution caused by the accumulation of hydrogen gas in the pickling tank, a set of acid mist purification tower is equipped. The acid mist is absorbed and neutralized by the spray, and a small amount of hydrogen is discharged through the pipeline.

The take-up Machine: Horizontal coiler ,Block collecting wire

Adopts a 450mm horizontal take-up machine, with a take-up wire collecting in coiler rack ;The take-up machine is driven by a chain wheel, with 2-sets 11kw take-up motors equipped with frequency converters and reducers. Each single disc is equipped with a full disc and a manual clutch for automatic parking.

Related products

-

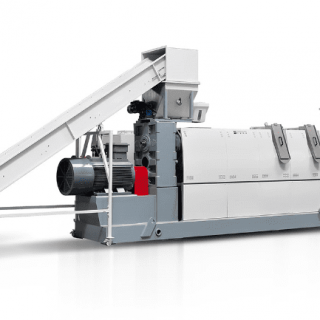

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

Oil-immersed transformer

Contact UsThe oil-immersed transformer is a new type of high-performance transformer with a more reasonable structure and better performance.

-

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line.

Reviews

There are no reviews yet.