12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Brushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m

https://www.g-wei.com.cn/12Kg-Medium-Torque-Brushless-Electric-screwdriver-Trigger-start-type.html

Special Features

➤ The unique structure of the independent patent cooperates with the

high-quality brushless motor, the function is more stable and longer

durability;

➤ The output speed is stable and the torque is accurate. When the preset

torque is reached, the motor automatically stops in order to protect the product

security.

➤ Adopt electronic control start-stop technology to get rid of the life limit

of mechanical structure and save after-sales cost;

➤ We are using eco-friendly materials on all of our parts and components to

protect the earth;

➤ The product is compact and easy to operate, suitable for long-term

operation;

Product Details

|

Model |

GW-B6212LF |

GW-B6212PF |

GW-B6318LF |

GW-B6318PF |

|

|

Voltage |

Input: AC 100~240V (50/60Hz), Output: DC LO 24V or HI 30V |

||||

|

Power |

60W |

||||

|

Torque |

Kgf.cm |

2~12 |

2~12 |

3~18 |

3~18 |

|

Lbf.in |

1.73~10.56 |

1.73~10.56 |

2.63~15.6 |

2.63~15.6 |

|

|

N.m |

0.2~1.18 |

0.2~1.18 |

0.29~1.76 |

0.29~1.76 |

|

|

Free Speed(r.p.m) |

HI |

2000 |

2000 |

2000 |

2000 |

|

LO |

1500 |

1500 |

1500 |

1500 |

|

|

Suitable screw(mm) |

Machine Screw |

1.7~3.0 |

1.7~3.0 |

2.3~4.0 |

2.3~4.0 |

|

Tapping Screw |

1.7~2.6 |

1.7~2.6 |

2.3~3.5 |

2.3~3.5 |

|

|

Weight(g) |

480 |

493 |

480 |

493 |

|

|

Bit Type |

φ5 |

φ5 |

φ5/HEX5 |

φ5/HEX5 |

|

|

Power Controller |

GW-30DC-60W (4P) |

GW-30DC-60WL (4P) |

|||

|

Cable |

4P |

4P |

4P |

4P |

|

1kgf.cm=0.098N.m 1kgf.cm=0.868Lbf.in

Dimension

Product details content

1. Brushless electric screwdriver product application scope.

Electronic products, plastic products, electrical products, electronic devices, etc.

2. The product quality standard of electric screwdriver is:

(1) Light weight and small size

(2) Safe low-voltage power supply

(3) The batch head is grounded to prevent static electricity

(4) Torque accuracy ±3%

(5) Speed control (high and low speed)

(6) Push, slide, push down switch

(7) Leverage Start

(8) With carbon brush and without carbon brush

3. When choosing a suitable electric screwdriver, you need to pay attention to the following points:

(1) Size of locking screws;

(2) Products with locked payment;

(3) Whether there are any requirements for the lock-up environment;

(4) Torque requirements of the electric batcher.

Related products

-

3MG132G CNC automatic track grinder for ball bearing inner ring

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2070mm*1320mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

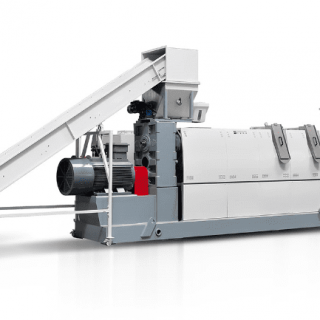

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

Reviews

There are no reviews yet.