Category: Mechanical Equipment & Tool Parts

Showing 81–96 of 137 results

-

LEIQING Series High Speed Diesel Engines (1680~2660kW)

Contact UsLEIQING Series High Speed Diesel Engines feature modular design for versatility and high reliability. Forged steel crankshaft, 4 valves per cylinder, and integrated cooling pistons extend service life. Quiet operation with reduced vibration. High-pressure common-rail fuel injection ensures strong power and optimal fuel economy. Equipped with high and low temperature circulating pumps for efficient cooling.

● Industrial Diesel Engine

● Power: 1680~2660kW

● rpm: 1500 -

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

-

MA-(2~8MM)×1800MM Steel Coil Slitting Line

Contact UsMA-(2~8MM)×1800MM Steel Coil Slitting Line is mainly composed by the following components : uncoiler, guiding device

-

MA-(3~12MM)×1800MM Steel Coil Slitting Production Line Manufacture

Contact UsMA-(3~12MM)×1800MM Steel Coil Slitting Production Line includes: uncoiler, guiding device, uncoiling tension device, coil head shearing

-

Main Parameters for CJWH Middle Torque Series Twin Screw Extruders

Contact UsCJWH series twin-screw extruders mainly focus on middle level customers with improved requirement for quality and efficiency.This series machine equipped with local made middle torque & high speed gearbox, the technology, configuration, performance and quality in the domestic leading level with competitive efficiency

-

Medical Waste Pyrolysis and Gasification Incinerator

Contact UsPyrolysis furnace can be categorized into fixed and continuous types, with the former designed for one-time feeding and the latter for continuous feeding. Within the category of continuous pyrolysis furnace, there are two subtypes: grate rotation and double rotation of grate and furnace body structures.

-

Motor temperature rise test bench

Contact UsMotor endurance cycle test bench, model: ZYDJ-9600 series, is loaded by an eddy current dynamometer

Control principle, customized test system to realize motor endurance cycle test. -

-

-

NEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Contact UsNEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

-

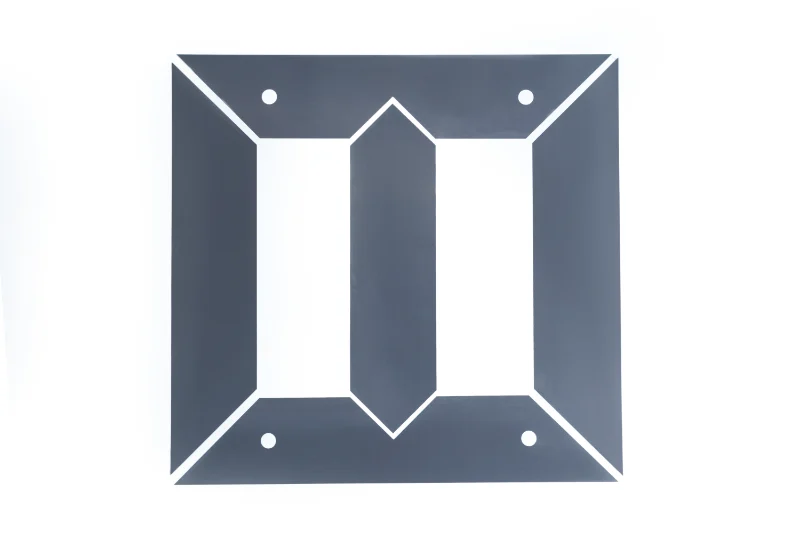

Oblique Cut Lamination

Contact UsShearing is a common cutting method for silicon steel sheets. Silicon steel is sheared with a carbide blade, which can cut the required size and shape. Shear method on the thermal impact of silicon steel core is small, the kerf is smoother, but the shear force is more damage, easy to produce deformation and burr. Therefore, the shear method is suitable for cutting smaller lamination, the requirement of surface flatness is not too high occasions.

Our company has introduced advanced oblique cut equipment, which is able to cut large silicon steel core to meet more needs of customers. -

Oil-immersed transformer

Contact UsThe oil-immersed transformer is a new type of high-performance transformer with a more reasonable structure and better performance.

-

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

Optimizing Quick Step Saw QS2500/4500/7000

Contact UsEquipped with patent optimizing software, QUICK STEP SAW QS2500/4500/7000 is design for high precision requirement working condition, and it is easy and safe to operate.

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.